Clay Bricks

Manufacturing ProcessBrick manufacturing process have not changed over time.

However, we have made contemporary brick plants substantially more efficient and have improved the overall products quality with the advancement of technology nowadays.

In addition, the rapid growth of the bricks’ industry is also attributed to the practicians’ intimate knowledge of raw materials, the high sensitivity of fire control and the best efforts to improve the quality of the kiln.

Intro

Phases of Manufacturing

The manufacturing process has 8 general phases:

1) Preparing and Extracting Raw Materials

2) Blending and Grinding

3) Screening

4) Shaping and Cutting

5) Drying the Brick

6) Firing

7) Cooling

8) Ready for Use

Bricks Process

How is the Process of Manufacturing Clay Bricks

1. Preparing and Extracting Raw Materials

- Soil being collected from the oil palm field

- Clean the soil by removing all the impurities

2. Blending and Grinding

- Blend the soil with other material.

- Breaking up, watering and kneading will be done on the mixed soil.

- The clay will go through a crushing and stiff-mud process.

3. Screening

- The process to check the clay pieces.

- Those oversize pieces will return to the pan mill for further crushing again.

4. Shaping and Cutting

- Adding water to the clay in a pug mill to shape the brick.

- Dry-press process will be applied.

- After mixed with water, the clay will press into steel molds under pressures by hydraulic.

- After cutting, the final shape of clay will be form.

5. Drying the Brick

- The bricks came out from cutting machines will send to dryer chambers.

- The drying process may take up to 24 to 48 hours.

- During this process, heat must be carefully regulated to avoid brick cracking.

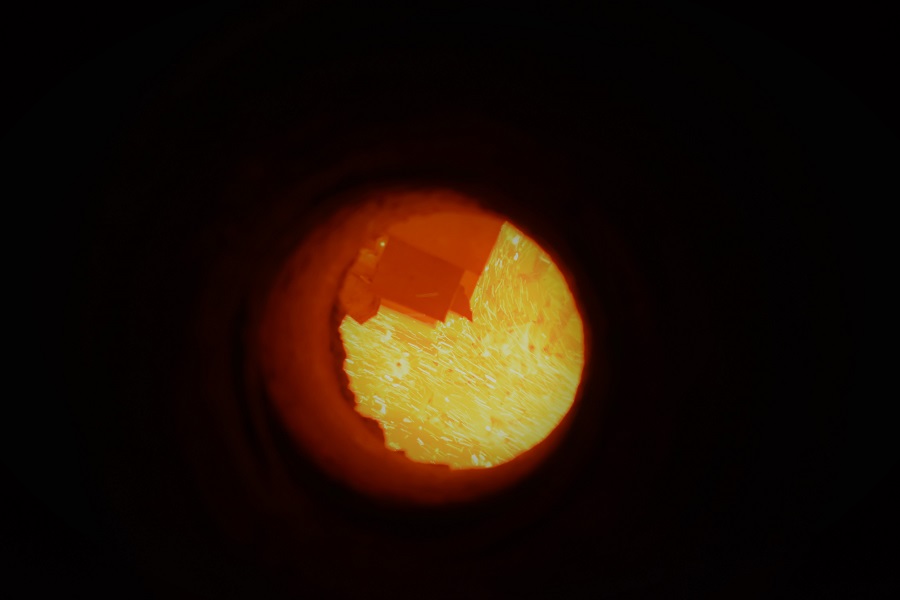

6. Firing

- The dry bricks will send to tunnel kiln for firing process.

- Kiln car will send the bricks pass through various temperatures zones which all are under controlled carefully.

- The bricks slowly become harder and more solid mass along the temperature increases in the kiln.

- The size, color and coring of the brick will be produced in this stage.

7. Cooling

- Cooling process will begin after the temperature of bricks has maintained for a prescribed time.

- This process will normally take up to 10 hours.

- It’s an important process because this process will directly affect the color of the bricks.

8. Packaging

- Bricks already for unloading.

- Sorting, grading and packaging will be done.

- Lastly, they are ready for delivery and distribute for sale.

Historical

Parksim Bricks’ equipment milestone

As Malaysia’s leading brick manufacturer, we continuously upgrade our factory so as to improve overall product quality as technology advances.

Video

“How bricks are made?”

video taken from YouTube, by Littlehampton Brick Co